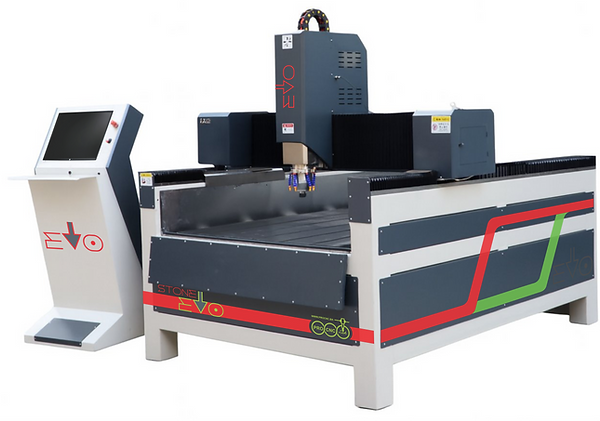

After more than 50 STONE 1812 machines delivered, we are moving to a new, more advanced model , STONE EVO.

DETAILS

IMPROVED TOOL COOLING AND CUT FLUSHING

STAINLESS STEEL WORKSPACE

PROTECTIVE ACCORDIONS ON ALL AXLES, PROTECTED WITH AXLES

CENTRAL LUBRICATION

HEIGHT SENSOR

Wireless joystick with rechargeable battery.

THE OFFER FOR THE FIRST 4 MACHINES HAS EXPIRED

Delivery of the new series of EVO machines is expected in April 2026. If you are planning a purchase, request a quote in time, our production capacity is limited.

Client works

your workshop can deliver such works in just a few months

"We introduced CNC with PROCNC without any experience - today we produce 3x faster"

PROCNC — CNC router for stone processing EVO

-

Work surface (X)1800mm * (Y)1200mm * (Z)280mm.

-

Profiled guides with 4 rows of recirculating balls.

-

Ball screw spindle with recirculating balls Z axis.

-

MACH3 or MACH4 control software.

-

CSMIO IP-M management interface (LAN connection).

-

Servo or stepper motors with encoder for accurate position calculation and feedback.

-

Racks with oblique contact and overload protection system.

-

3500-5500W, 3000-24000rpm machining motor with appropriate power frequency converter and support for motor control via 0-10V input, suitable for axial and radial loading.

-

Inductive position sensors on all axes.

-

Construction made of steel profiles and stainless steel sheets for water drainage.

-

Emergency switch.

-

Dual drive along the X axis.

-

Accordions (dust protection) on longer axes.

-

Automatic vertical alignment of the bridge.

-

Central lubrication.

-

Computer with 19-inch monitor integrated into the control cabinet.

-

Water supply for cooling the workpiece with automatic on/off.

-

Base with channels for easy clamping and cleaning (industrial plastic).

-

Supply voltage 3x380V or 220V, connection power depending on the option.

-

Weight 1100kg.

WE SPECIALLY HIGHLIGHT

INDUSTRIAL CHILLER

CHILLER is a device that actively maintains the temperature of the water for cooling the processing engine. It cools the water to the set temperature with a compressor cooler, and heats it if necessary. In addition to the temperature, this device also controls the flow, and alarms if there is no flow. In this way, the processing engine on the STONE EVO cnc machine always works at an optimal temperature, which significantly extends its working life.